High voltage non-destructive analysis of winding identifies

difficult to detect manufacturing faults

There are a number of parameters that can change during

manufacture that may affect the performance of a winding. These

parameters, which cannot always be measured with an LCR meter,

include change in material as well as shorted and damaged

windings.

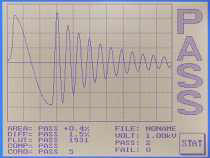

The 7720 Impulse Winding Tester uses a very high voltage impulse

to stimulate the device under test (DUT). It analyzes the

decay waveform to detect changes in material, shorted and damaged

windings and other errors. Long term decay of a winding can

also be detected.

The system used ensures that the component is tested but not

damaged during the analysis process.

The shape of the waveform is dictated by the Q factor, inductance

and stray capacitance of the winding. High Q shows as a slow decay

and the frequency of the waveform is determined by the inductance

and stray capacitance of the DUT. Importantly, the short high

voltage pulse causes no damage to the device under test.

Simple operation, powerful detection capability and inexpensive

... a winning combination

The 7720 provides an important test capability in the production

process for any wound component manufacturer.

Early detection of component faults is a key feature of the

7720. Faulty material, manufacturing process defects and bad

components can be identified early in the process. This saves

money for the manufacturer and it ensures the quality of the product

supplied to the customer.

The 7720 has also been designed with ease of use in mind - using

a large visual display, graphical format and straightforward

intuitive operation. The 7720 provides all this capability at a very

attractive price.

Production test software

7720 is fully programmable through its RS232 port.

Specialised production test software is available as an

option. Component readouts can be stored against serial

numbers to ensure thorough and rigorous testing of components.

Clear and simple display with automatic

PASS/FAIL

Technical specifications

Measurement ParametersArea under curve

Differential area

size

Flutter (corona) value

Waveform comparison.

Voltage Range 200 V to 5 kV (100 V Steps)

Test Voltage Accuracy±2%

Measurement Time

50 ms

Memory200 waveforms

InterfacesRS232, parallel printer

Measurement Connections2, 4, 6 or 8 self latching

connectors

Display320 x 240 dot with back lighting

Power requirements115/230 V ±10%, 50/60 Hz

Operation temperature range0°C to 40°C

Storage temperature range-40°C to 70°C

Relative humidityUp to 75%

DimensionsW 425 mm, H 190 mm, D 350 mm

Weight20 kg

Order codes and options

| 7720 2 port Impulse Winding Tester |

|

1J7720/C2 |

|

| 7720 4 port Impulse Winding Tester |

|

1J7720/C4 |

|

| 7720 6 port Impulse Winding Tester |

|

1J7720/C6 |

|

| 7720 8 port Impulse Winding Tester |

|

1J7720/C8 |

|

| All units supplied with user manual, 2 m AC

power cable and test connectors. |

|

Accessories |

| Production Test Software |

|

PT7720 | |